- Heavy Duty Wholesale Horizontal Slurry Pumps

- China Vertical Slurry Sump Pumps

- Dredge Gravel Pumps

- - ST-2 (2inch x 2inch) Solids Handling Self-Priming Trash Pumps

- - ST-3 (3inch x 3inch) Wet Priming Self Priming Pumps

- - ST-4 (4inch x 4inch) Heavy Duty Solids Handling Trash Pumps

- - ST-6 (6inch x 6inch) Wet Prime Self-primer Pumps

- - ST-8 (8inch x 8inch) Self Priming Centrifugal Trash Water Pumps

- - ST-10 (10inch x 10inch) Self-Primer Sewage and Trash Pumps

- - SU-3 (3inch x 3inch) Heavy-Duty Self-priming Sewage Pumps

- - SU-4 (4inch x 4inch) Self-Primer Solids Handling Trash Pumps

- - SU-6 (6inch x 6inch) Self Priming Centrifugal Sewage Pump

- - Super ST-3 (3inch x 3inch) High Suction Lift Self Priming Trash Pumps

- - Super ST-4 (4inch x 4inch) Low Pressure Heavy Duty Solids Handling Self-priming Pumps

- - Super ST-6 (6inch x 6inch) Horizontal Self Priming Centrifugal Sewage Pumps

- - Super ST-8 (8inch x 8inch) Self-priming Non-clogging Centrifugal Sewage Pump

- - Super ST-10 (10inch x 10inch) Self-priming Wet Prime Pumps

- - 3inch x 2inch C Settling Slurries Coarser Particles Handling Slurry Pump

- - 4inch x 3inch C Diamond Concentrate Cyclone Slurry Pump

- - 6inch x 4inch Mill Discharged Tailing Delivery Slurry Pump

- - 8inch x 6inch Power Plant Ash Removal Slurry Pump

- - 10inch x 8inch E-ZM Fine Primary Mill Grinding Slurry Pump

- - 10inch x 8inch FST Mineral Processing Cyclone Feed Slurry Pump

- - 12inch x 10inch Heavy Duty Mine Dewatering Slurry Pump

- - 16inch x 14inch Aggregate Processing Rough Solids Conveying Slurry Pump

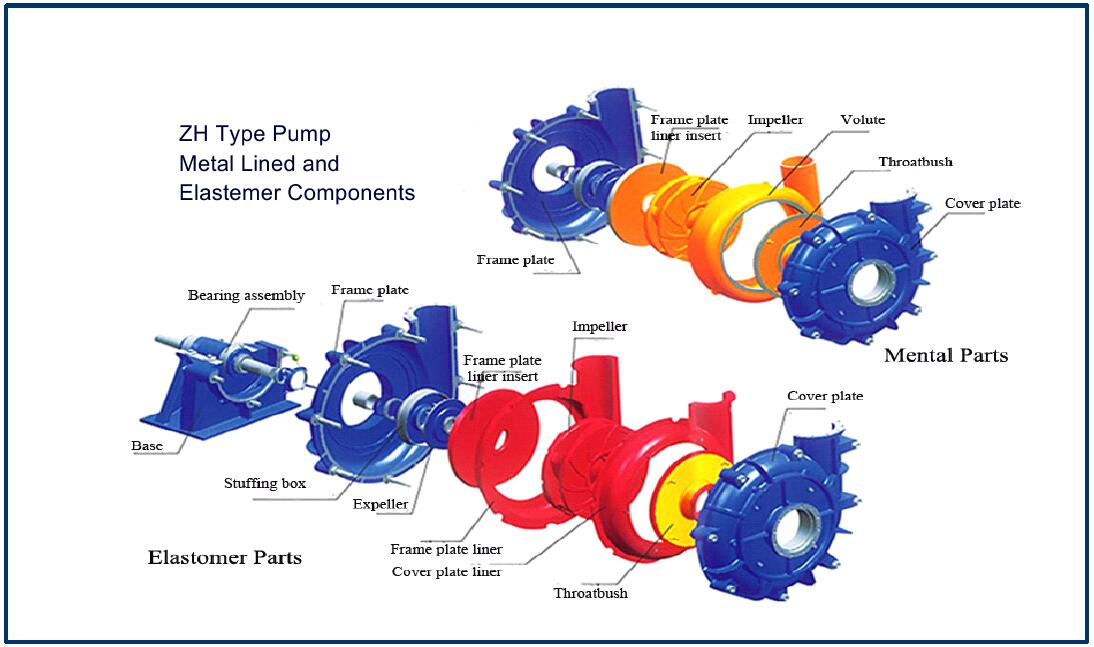

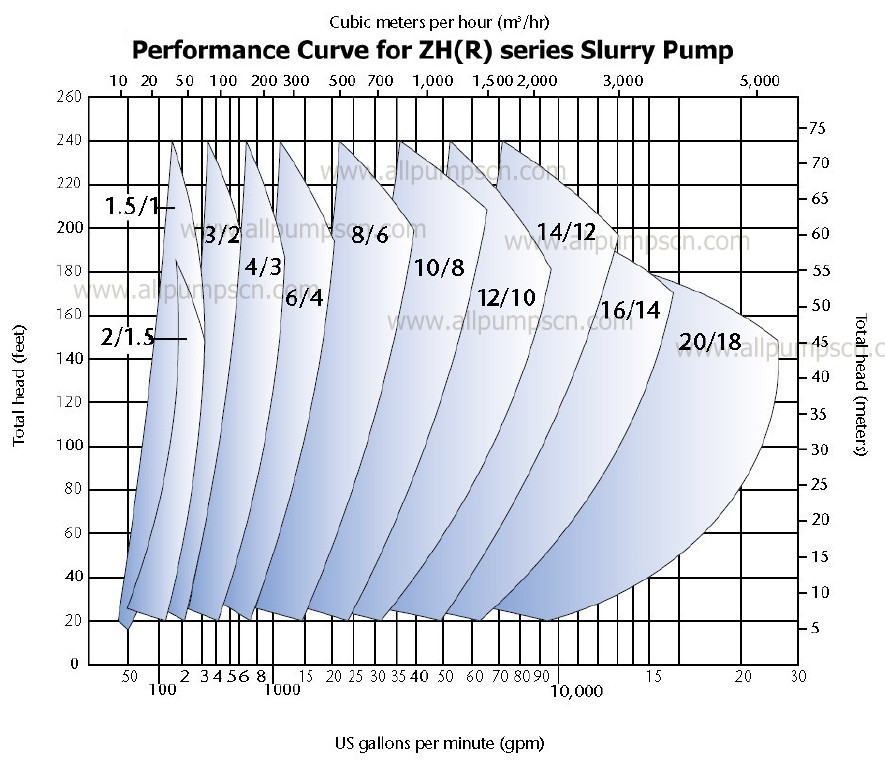

- - ZH Alloy Slurry Pump

- - 1.5inch x 1inch B Small Gold Mine Rubber Liners Slurry Pump

- - 2inch x 1.5inch Polyurethane Erosion Resistant Material Lined Slurry Pump

- - 3inch x 2inch C Gold Leaching Cyanide Slurry Pump

- - 4inch x 3inch C Pulp And Paper Rubber Lined Slurry Pump

- - 6inch x 4inch D Copper Ore Chemical Slurry Service Pump

- - 8inch x 6inch E Pulp and Paper Industry Anti-Corrosive Rubber Slurry Pump

- - 10inch x 8inch E-ZMR Corrosion Resistant Rubber Slurry Pump

- - 10inch x 8inch F Rubber Lined Slurry Pump for Line Applications

- - ZHR Rubber Slurry Pump

- - 40PV Heavy Duty Cantilever Sump Pump with Extension Shaft

- - 65QV Rubber Vertical Sump Slurry Pump for Mineral Tailing Tank

- - 100RV Semi-submersed Vertical Hole-in-the Ground Slurry Handling Pump

- - 150SV Vertical Sump Semi-Submersible Slurry Pumps

- - Fine Tailing Processing Centrifugal Slurry Pump

- - ZP(R) Vertical Sewage Spindle Pit Sump Slurry Pump

- - ZPR Vertical Rubber Slurry Pumps with Extension Pipe

- - End Suction Centrifugal Pumps

- - Back Pull Out End Suction Water Pump

- - Horizontal Single Stage End Suction Centrifugal Pump

- - Vacuum Prime Assist Pumps

- - Prime Vacuum-assisted Self-priming Trash Pumps

- - Vacuum-assisted Priming Centrifugal Pumps

- - FEP Lined Chemical Centrifugal Pumps

- - LGH Series Centrifugal Chemical Process Pumps

- - IHK Series Open Impeller End Suction Chemical Pumps

- - FRP Chemical Pumps

- - API610 Chemical Pumps

- - Micro Magnetic Drive Pumps

What are you looking for?

EN

EN

fr

fr  de

de  es

es  ru

ru  pt

pt  ar

ar  vi

vi  hi

hi  id

id  af

af